What is Cellulose?

Cellulose is the most abundant organic biopolymer on earth.

Trees contain 35-50 % cellulose and we have plenty of well kept forests in Finland.

Events

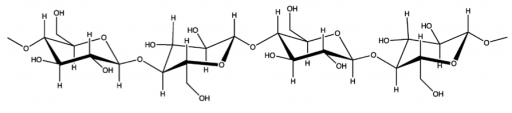

Cellulose is chemically very simple – a polymer made of glucose units.

Physically cellulose is complex – details of the cellulose structure are still under debate. Read a more about cellulose from the Wikipedia.

Cellulose is the material of the future

Wood cellulose has traditionally had a remarkable role in Finnish industry, although the products have been mainly high volume and low added value products with no design involved. Now we are looking for new ways to develop the field. The design-driven approach enables generation of low-volume, high-value industry to the arena. By combining both large-scale high volume and small-scale high added value businesses together the cellulose ecosystem is expected to be stronger in the global market also in the future.