Team : Sanna Siljander, Pasi Keinänen and Anna Räty (TUT), Atsushi Tanaka and Jani Lehmonen (VTT), and Anastasia Ivanova (Aalto University)

BACKGROUND

The research aim was to achieve optimum conductive properties to cellulose based non-woven, using minimum amount of materials and chemicals, and with minimum processing steps. In the developed process, sonication is used to homogenize the dispersion of carbon nanotubes (CNTs) and nanocellulose. The dispersion is mixed with matrix fibres (e.g. cellulose pulp and viscose staple fibres) using foam forming. The produced conductive material can be in the form of non-woven textile or thick 3D-shaped element.

CHARACTERISTICS

Due to the used materials and processes, every single cellulose fibre in the created material structure is conductive. The maximum achievable temperature in a heating structure is adjusted already in the production process by the amount of carbon nanotubes. CNTs act as a fire retardant.

TECHNICAL DATA

Heating of total volume – no hotspots. No fire hazard. Customization of the maximum temperature is possible. Low voltage (e.g. 9V) can be used in products, which means that they are safe and easy to install. Rapid cooling. No chemical reactions.

POTENTIAL APPLICATIONS

There are limitless possibilities for using this invention in different applications. The conductive non-woven or element is also possible to implement inside different structures. Examples: Boat cabin walls, car interior panels and office chairs.

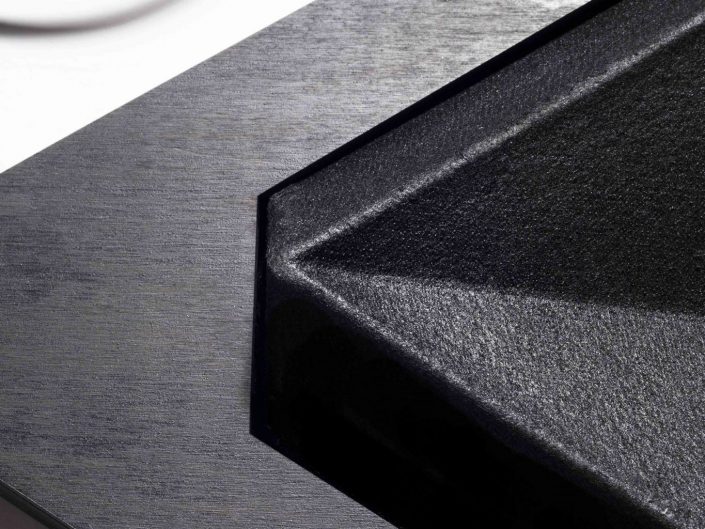

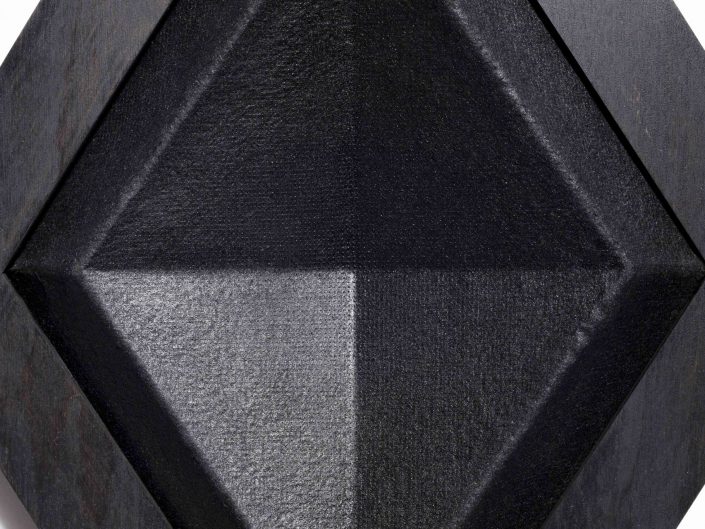

Heating element — Salmiakki

Materials: Pulp and viscose fibres, carbon nanotubes and nanocellulose.

Process: Foam and mold technology.

Team: Sanna Siljander (TUT), Jani Lehmonen and Atsushi Tanaka (VTT), and Anastasia Ivanova (Aalto university).

3D Render: Anastasia Ivanova

Photos: Eeva Suorlahti