TEAM: Vesa Kunnari (VTT), Heidi Turunen (Aalto University), Timo Kaljunen, Jaakko Pere, Ali Harlin, Ulla Salonen, Vuokko Liukkonen (VTT), Jyri Roppola (TUT, student), Kirsi Kale (Omnia, student)

BACKGROUND

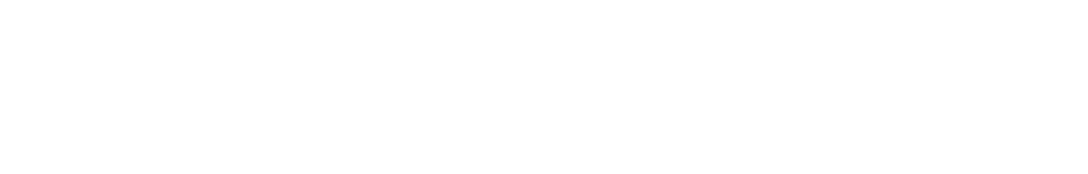

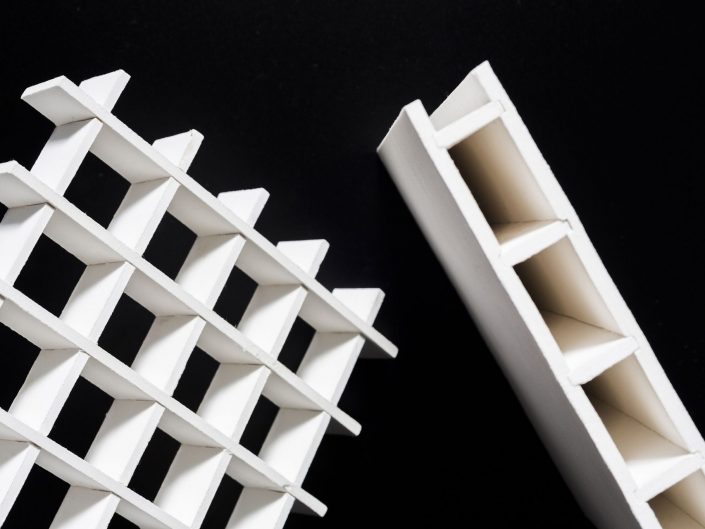

Method to produce a novel laminated material structure combining nanocellulose and cellulose has been developed. No additional glue is used. Method has been demonstrated by creating interior architectural design elements.

CHARACTERISTICS

Material is strong and light. Various finishing possibilities include embossed patterns, printed pictures and painting of surface. Wet material is possible to shape to 3D forms. Drilling and sawing of the material is possible by using conventional woodworking tools.

Material is totally bio-based and bio-degradable.

TECHNICAL DATA

Bending strength of this novel structure is 28 N/mm2, which is higher than the strength of the tested reference materials chip board (8 N/mm2), gypsum board (EH, 10 N/mm2), MDF (26 N/mm2) and softwood plywood (22 N/mm2).

ECONOMY

Competitive raw material price, simple production process

POTENTIAL APPLICATIONS

- Interior architectural design elements

- An alternative for domestic dividing walls like gypsym and chip board

- Office dividing walls being light and sound absorbing

- Furniture

Photos: Eeva Suorlahti