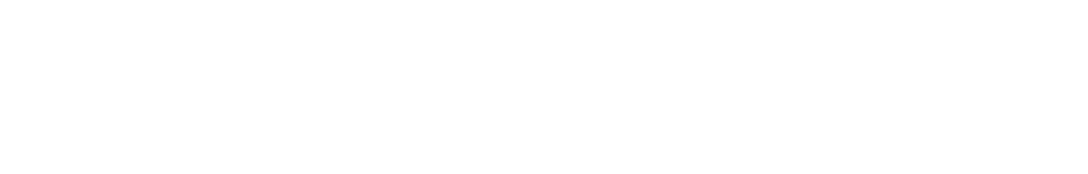

Nanocellulose can be processed using molding technology to extremely light and strong tubular structures. With material thickness less than 1 mm, it is strong enough for numerous load bearing applications.

Demo Products

Nanocellulose bike

Design and manufacturing: Kim-Niklas Antin,

Nanocellulose tubes: Tiina Härkäsalmi

Composites fabrication and finishing: Tuomas Pärnänen

Tube materials: CNF/VTT

Knitted reinforcement: Ioncell-F filament/ Sherif Elsayed Aalto/CHEM

Stool

Design and made by Tiina Härkäsalmi

MATERIALS

Tubes: CNF/VTT

Knitted reinforcement: Ioncell-F filament/ Sherif Elsayed Aalto/CHEM

Veneer/Mahogany Ltd

PLA nonwoven

Linen (fabric)

Birch

Corrugated CNF Sheets

by Tiina Härkäsalmi

Photos: Eeva Suorlahti